| Tags | show all posts |

Aramith Balls - History of Saluc

Aramith Pool and Snooker Balls - History and Profile of the Company - 'Saluc'.

The Aramith pool and snooker balls are legendary worldwide in cue sports. These superb balls are manufactured in Belgium by Saluc. This is a brief history of the company and why its products remain the number one in the world to this day. Having recently visited Saluc, we can vouch for the quality and professionalism of this famous compnay.

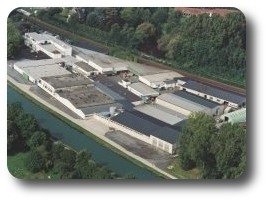

Saluc - The Factory

Today, Saluc produces and distributes billiard balls under the registered trademark Aramith in more than 85 countries and has an 80% market share worldwide.

Saluc's expertise extends beyond cue sports. The company is a leader in the production of industrial balls for various applications, 9-pin bowling balls, and trackballs. A staggering 98% of its operations are dedicated to exports.

One of the company's major strengths is its upstream integration: Saluc has its own chemical plant to produce the phenolic resin that gives exceptional characteristics to the finished products. This integration allows price optimisation and quality insurance that makes Aramith Balls the best in the world.

The Aramith legend : Inside Pool's story on Saluc, the Belgian billiard balls manufacture

LEGENDARY REPUTATION

It's a little-known fact that a small village in the Belgian countryside is the source of nearly 80% of the world's billiard balls. For over 50 years, SALUC SA has been quietly producing the renowned Aramith phenolic balls, turning this unassuming village into the global hub of billiard ball production. But how did a company in a region not traditionally associated with billiards become a major player in the industry?

"Saluc was established in nineteen twenty-three and was at the time specialised in manufacturing synthetic tannins in Callenelle, supplying to about forty tanneries in the area," said Curt Bossuyt, CEO. "After the Second World War, the quasi-total disappearance of this industry in the region and the tough competition of some chemical giants progressively compromised Saluc's activities and forced the company to look for alternatives."

THE KEY FACTOR OF ARAMITH BALLS: PHENOLIC RESIN.

Based on its chemical know-how in manufacturing phenolic resins, Saluc detected a valid opportunity in the conversion to making billiard balls. "This choice had two reasons," said Bossuyt. "The phenolic resin features excellent physical and chemical characteristics. In addition, the billiard market was in full expansion."

The commercialisation of the first balls started in the sixties when competition against three already well-established manufacturers was brutal. Through continuous quality fine-tuning and increased production levels, Saluc succeeded in taking a significant competitive lead. Today, Saluc is the only company worldwide producing phenolic billiard balls, exporting over 99% of Aramith balls to more than 60 countries.

Unlike polyester, the phenolic resin used by Saluc is specifically designed for billiards and is produced in-house. This unique technology results in a material with unmatched characteristics, such as chip- and scratch-resistance. 'Aramith balls last up to five times longer than polyester balls,' says Yves Bilquin, sales and marketing manager for North America. 'Their unique structure, more than one hundred times finer than mineral-filled polyester, gives them their specific reactivity and allows them to maintain their high-gloss polish over time, leading to minimal ball and table cloth wear'.

'There's simply no comparison,' says Vito Leo, a PhD in material science and solid state physics and an associate professor at the Université Libre de Bruxelles. Leo conducted independent tests on a specially designed billiard table simulator. 'When we tested all types of polyester balls on the market, including DAP-based and other types, both the cloth and the balls were significantly damaged after a short period. Some were even destroyed. In contrast, the Aramith balls, along with the cloth used, maintained an exceptional shape even after extensive longevity tests.'

On top of that, high-end phenolic balls feature an extra-hard, dense, and translucent vit-On top of that, the high-end phenolic balls vitrification layer gives exceptional characteristics to the products. "These characteristics make the Aramith ball sets easy to sell to retailers," reported Bilquin. "We provide training on dealers' requests that allow the sales staff to explain why the phenolic resin is a natural choice and why upgrading to a higher-end Aramith set gives value to the player. That way, the retailer ensures customers the highest satisfaction and the lowest yearly cost, thanks to the low table and cloth maintenance the Aramith balls provide.

Pool Rooms, all mainly using Aramith balls only, give more evidence that with Aramith balls one can satisfy the demanding player while still minimising cloth and ball-operating costs."

Thanks to the upstream process integration, tight control of the raw material is possible. The thirteen-step production process lasts up to 23 days and includes casting and curing processes combined with unique grinding state polishing technology.

Computerised technology continuously interfaces with and assists craftsmanship to guarantee the tightest tolerances and specifications throughout the process. Regardless of the automated and statistical quality controls used, each Aramith ball is still checked manually before leaving the factory to provide the worldwide distribution network with reliable output.

USED BY ALL THE PROS.

The Aramith ball sets are the reference used in virtually all events and tournaments worldwide, whether in pool, snooker, or carom disciplines.

Organisations such as the United States Professional Pool Players Association, the American Pool Player Association, and many others have appointed Aramith as the exclusive official ball used in their tournaments.

The pool set chosen, as seen on TV, is the Super Aramith Pro-Cup ball. It features the famous design-protected six red dots cue ball that cumulates razor-sharp precision with visualisation of the rotation, which is a big help for both the viewers and the players. This new product is often requested by amateurs and pros alike.

ARAMITH, A NEW REFERENCE FOR CUES

“Bringing value for the end-user and value for the trade has been Aramith’s baseline for its success. This is why Saluc decided to integrate its knowledge, skills, and know-how in relation to the balls to optimise the design of other products that interact with the balls,” explained Bilquin. As such, besides a whole new range of high-quality table accessory kits and ball and cue cases, the company disclosed during last April’s BCA trade show a break-through ultra-low deflection shaft and cue program.

This cue is designed to become a new reference in the cue industry based on several new high-tech components and advanced technologies, including the Acuerate technology. Endorsed by several professional players, its attractive price will allow every player access to a high-end cue with proven low-deflection capabilities.

A WHOLE RANGE WITH THE TIGHTEST SPECIFICATIONS.

Numerous other varieties of billiard games exist worldwide, including pool, snooker, and carom. In addition to more than 800 billiard types, Saluc makes Aramith balls ranging from 3/8 inch to over 7 inches for applications ranging from industrial, computer, and medical to 9-pin and duck-pin bowling balls.

The Aramith phenolic resin is manufactured in several varieties, from the Premier quality to the PREMIUM to Super Aramith (used most in high-precision carom balls) and Super Aramith PRO, used for the top-of-the-line pool balls. With the increasing quality, the resin gets a finer grain, resulting in fantastic polish that remains over a long period. Most importantly, though, through the different hardening steps, the material receives a transparent vitrified surface that is highly wear-resistant, making the ball and the cloth last a lot longer.

Regardless of the quality level, all Aramith balls are controlled along seven essential criteria: density, balance, diameter tolerance, roundness, colour precision, surface polish, and brilliance.

The Premier variety is the most widely known because of its excellent price-to-quality ratio. Still, the PREMIUM variety was recently introduced as the next generation to the Premier quality to ensure even lower yearly ball and cloth costs. With its Vitrotech technology, the PREMIUM ball surface is completely through-hardened, giving it its unique transparent vitrified surface and increasing the surface density and, hence, its longevity.

Its excellent molecular structure has been engineered to resist high-friction temperatures when the ball slips into a roll. As its surface doesn’t rough up, it keeps its smooth polish a lot longer and won’t rough up the cloth, making a lot of dollar difference for the table operator.

As the top-of-the-line, the Super Aramith PRO set distinguishes itself by its beautiful design, numbers, and maximised in-depth vitrification. More importantly, it is a fully matched professional set, where precise calibration of each ball guarantees maximum consistency within the set.

The Super Aramith PRO also exists in the Centennial design produced for Brunswick.

Contrary to popular belief, the primary characteristic of a billiard ball is not just its diameter tolerance or roundness. While these aspects are important, they are relatively easy to achieve. The true measure of a high-quality ball lies in its precision, particularly in the rail mounting. Even the best ball tolerance is only as enjoyable as the precision of the rail mounting, which is always much lower than the ball. This is where Aramith billiard balls excel, instilling confidence in their quality and precision.

That’s why the quality and precision of the game are dictated much more by the balls’ raw material, molecular structure, density, and rebound quality.Too much rebound or too little results in erratic ball behaviour, making shots and ball repositioning random.

Chemical production processes are also critical, as they may seriously influence the balls’ balance. A lack of balance results in a zigzagging roll, controlling the contact point between two balls and making you wonder why you missed that shot.

Finally, on the high-end side of the line, the rate of consistency for all these characteristics between any balls within that same set is almost perfect because it is essential for professional play. That’s the case of the Super Aramith PRO ball sets, which are individually matched to constitute a quasi-per-fact homogeneous set.

This is why Aramith Balls have been exclusively selected by practically all professional federations and championships worldwide for decades. These top-of-the-line specifications are also applied to snooker and carom professional ball sets. No wonder that in the carom discipline, which many consider one of the most difficult disciplines in billiard sports, Aramith balls are undisputedly the only brand being admitted.

WHAT NEXT?

The world of billiards is evolving, and so are the players. They are increasingly demanding high-performance products. Now, league players are bringing their own ball sets to ensure they are playing with a quality product, rather than relying on a lesser-maintained, lower-end set found on the table. This shift is a testament to the integral role each player plays in the billiards community, and Aramith is committed to meeting their high standards.

“To address these more demanding and discriminating players, Aramith is developing new attractive high-end products such as cases, which allow players to hold a set and cues,” said Bilquin. We will work more closely with the trade to make these products readily available to retailers and pool rooms.

“Billiards is a sport of passionate people. We, as manufacturers, are as passionate about supplying players and trading with the products that make them enjoy their sport while increasing their performance. Aramith is committed to bringing value to the end user and the trade.”